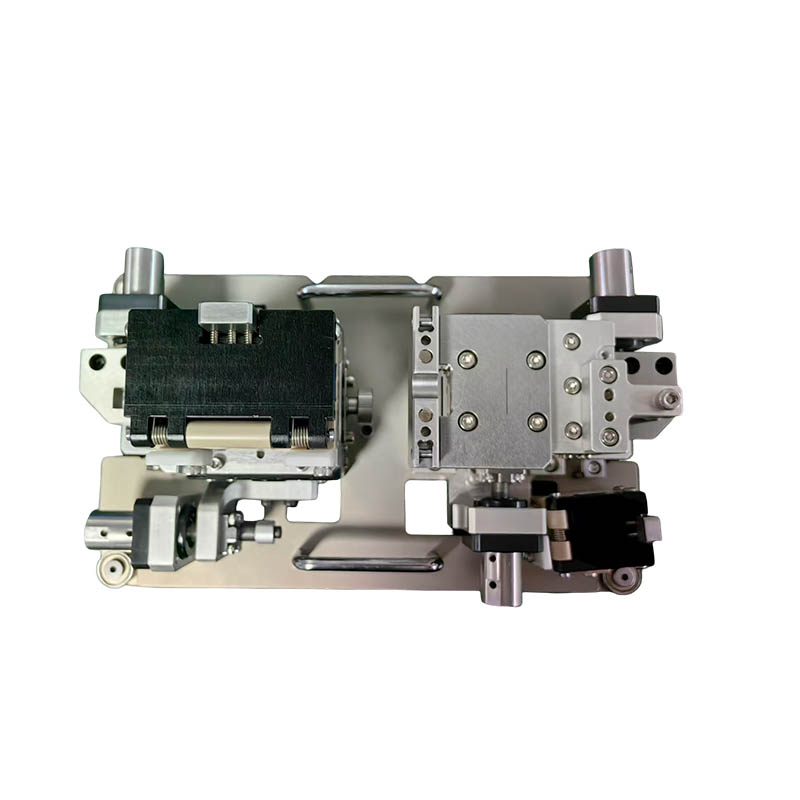

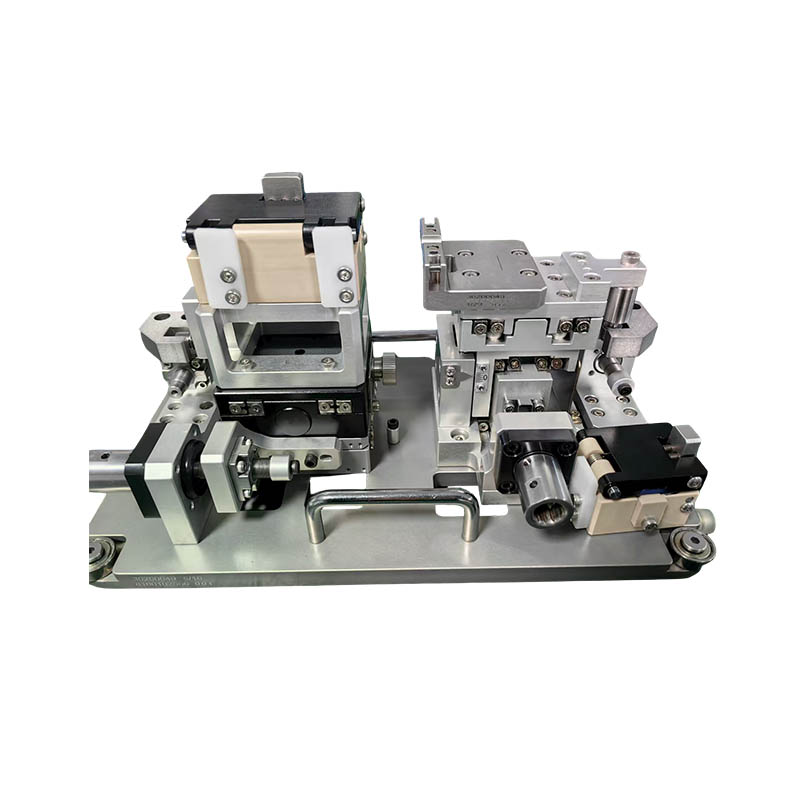

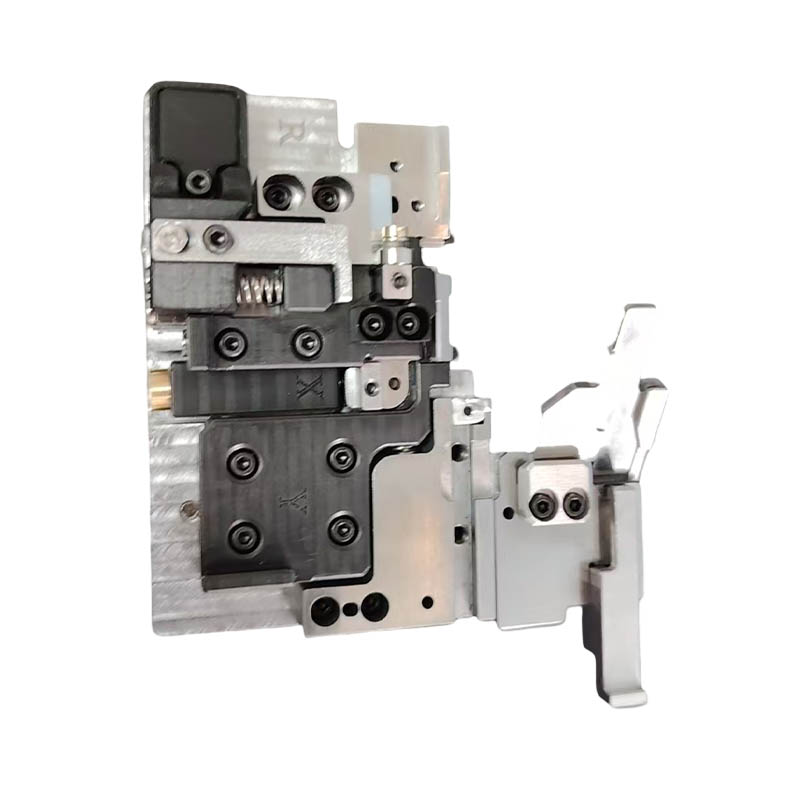

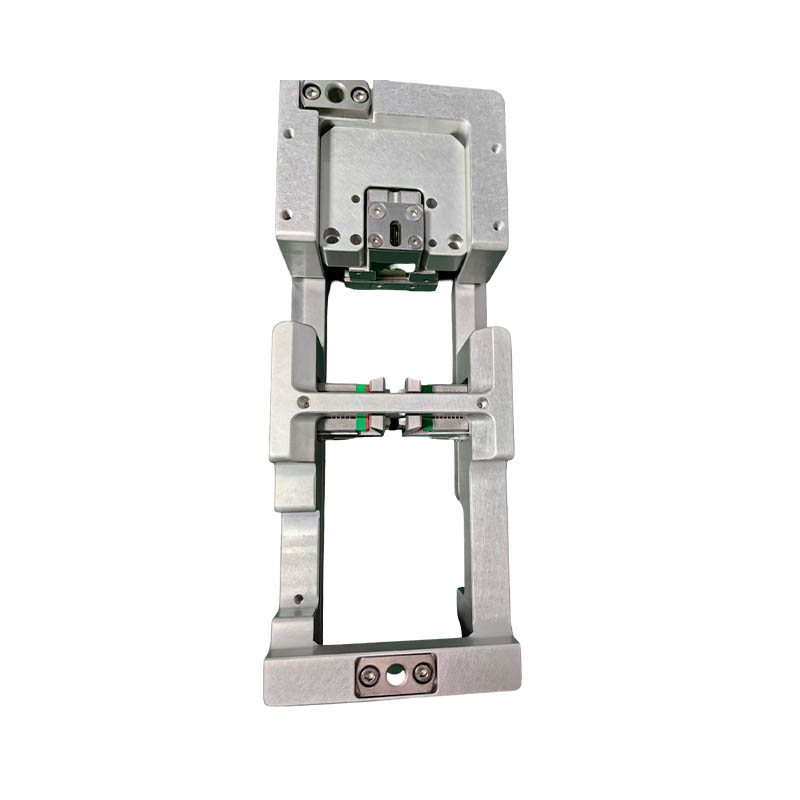

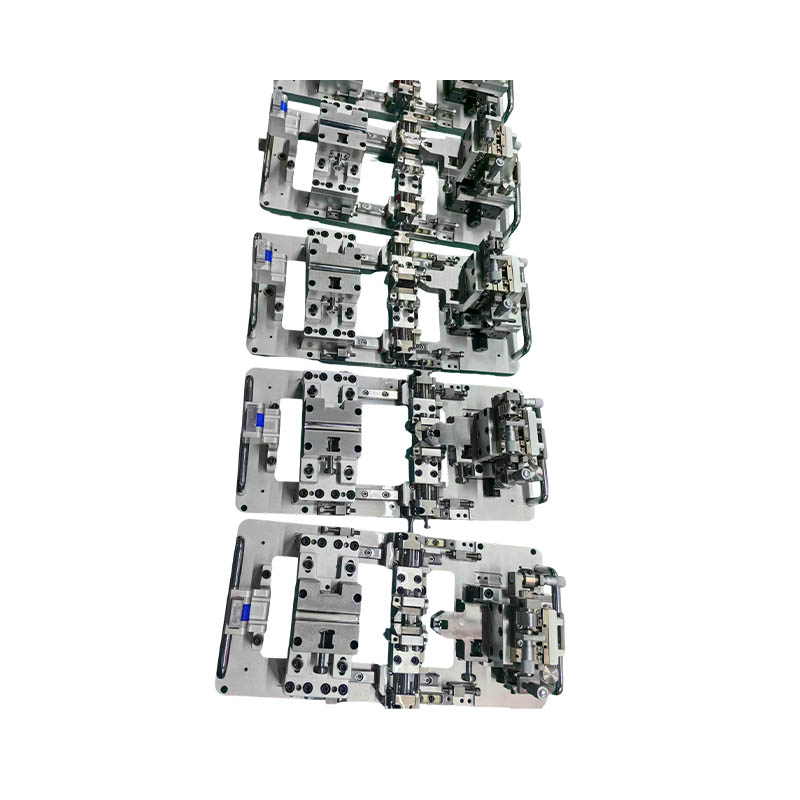

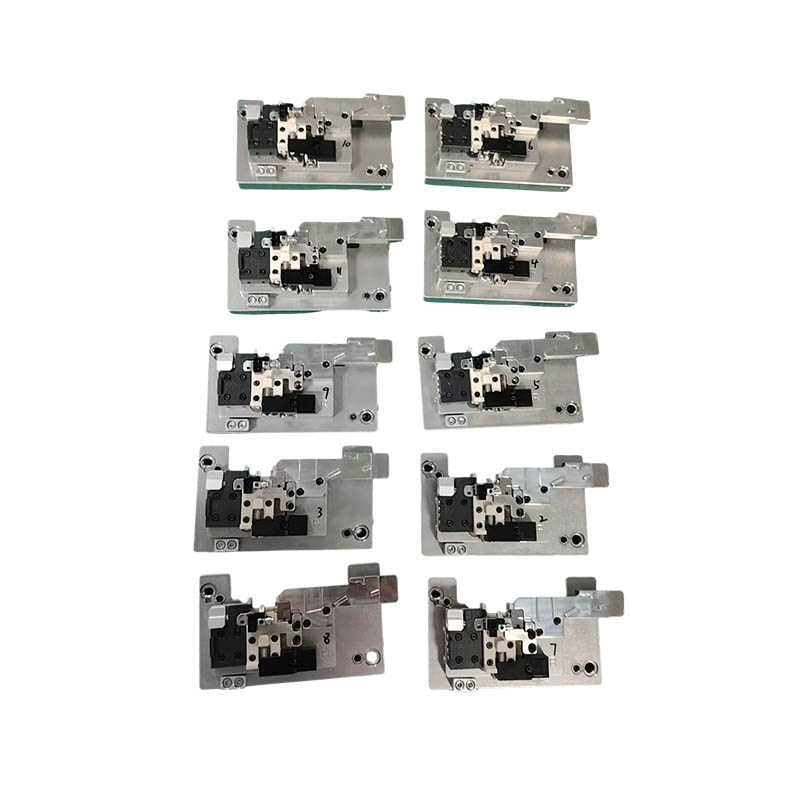

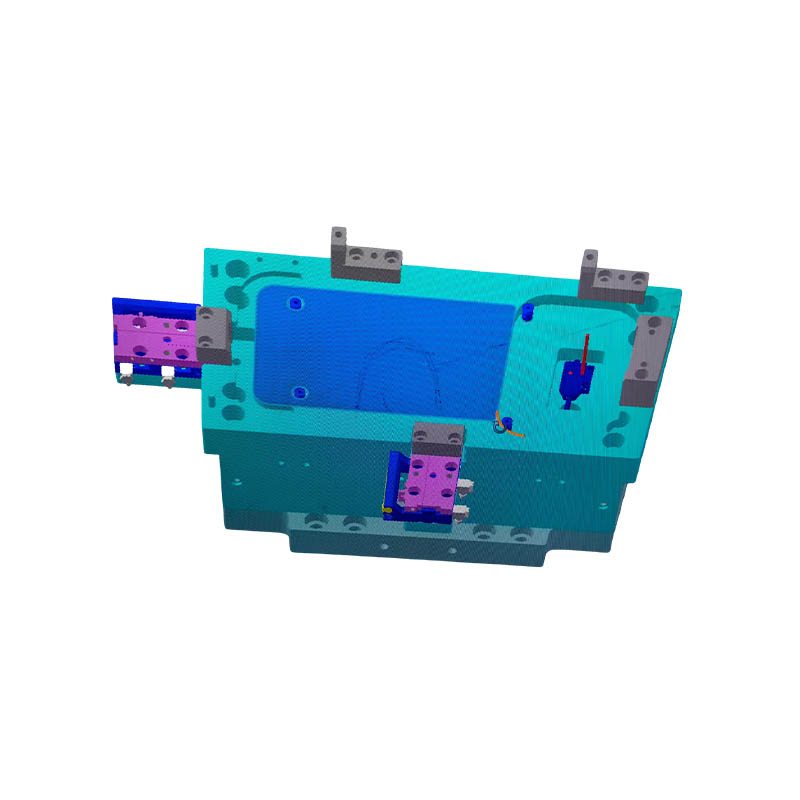

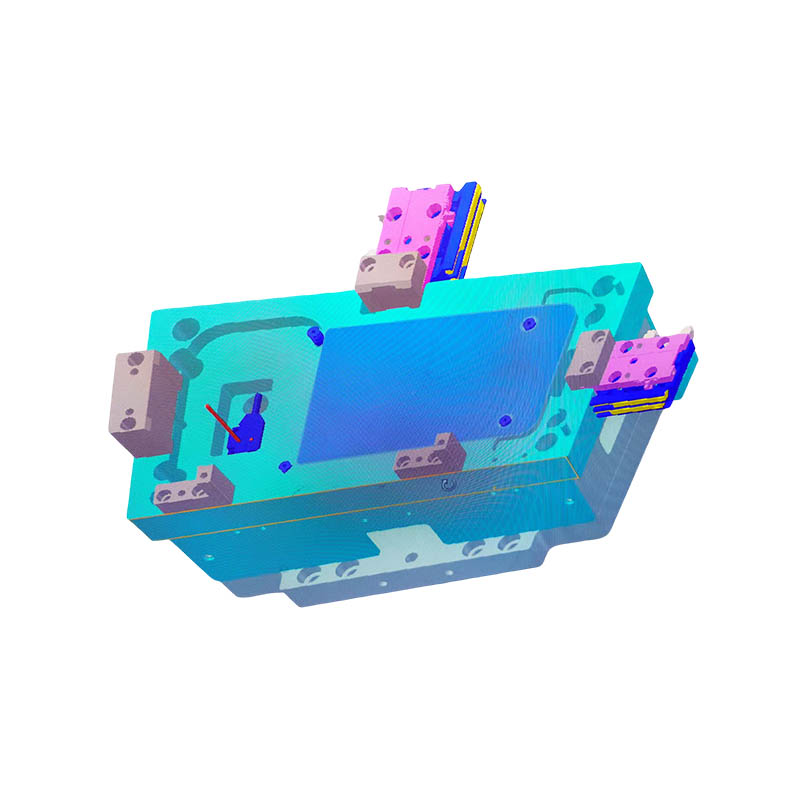

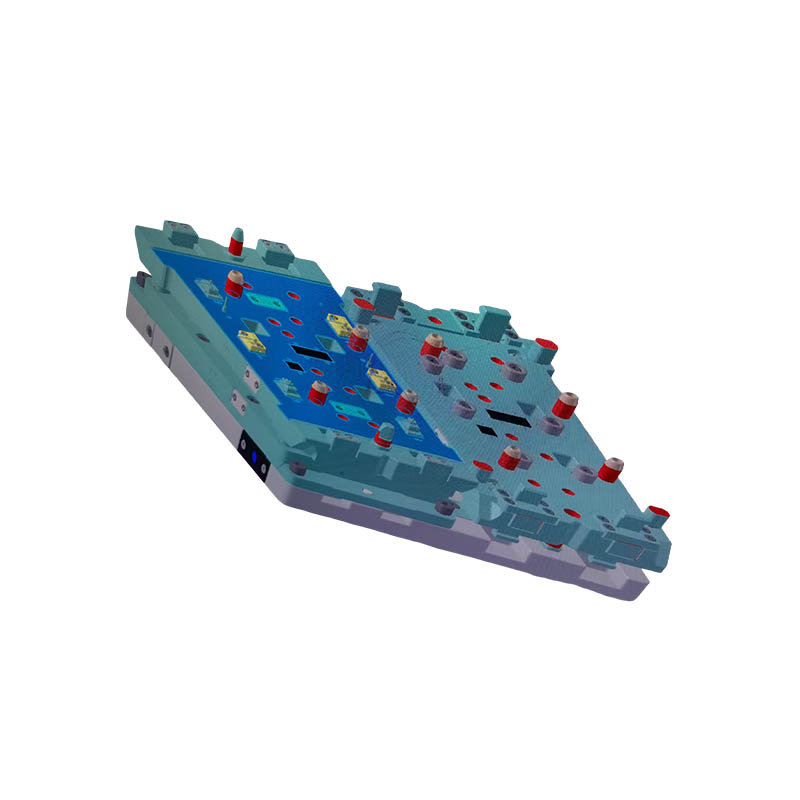

Customized Processing Of Carriers, Inspection Tools, Fixture Components And Finished Assembly Parts

We support sample making according to provided drawings and sample customization. Our advanced production technology can produce various carriers, inspection tools and fixtures on demand and assemble them into finished products to complete orders with guaranteed quality and quantity.

Equipped with high-end equipment such as five-axis machining centers and wire-cut EDM machines, these products achieve one-step molding of complex curved surfaces with a machining accuracy of ±0.002mm. They master the molding process for high-strength aluminum alloys, titanium alloys, and engineering plastics, meeting the dual demands of lightweight and high strength. They are widely used in the automotive, electronics, and medical fields.