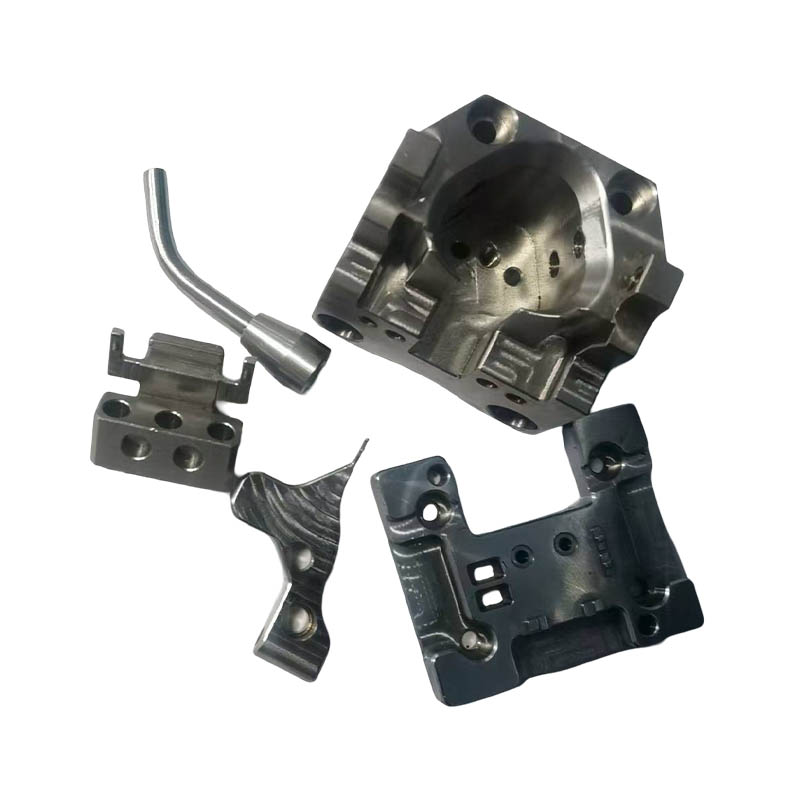

Precision hardware machinery parts processing is the "tiny cornerstone" supporting system performance and reliability. These parts are often tiny in size, complex in structure, and have stringent tolerances, demanding extremely high standards for surface

- +86-15050431002

- 15050431002@163.com

- No. 85, Huichang Road, Huishan District, Wuxi City, Jiangsu Province